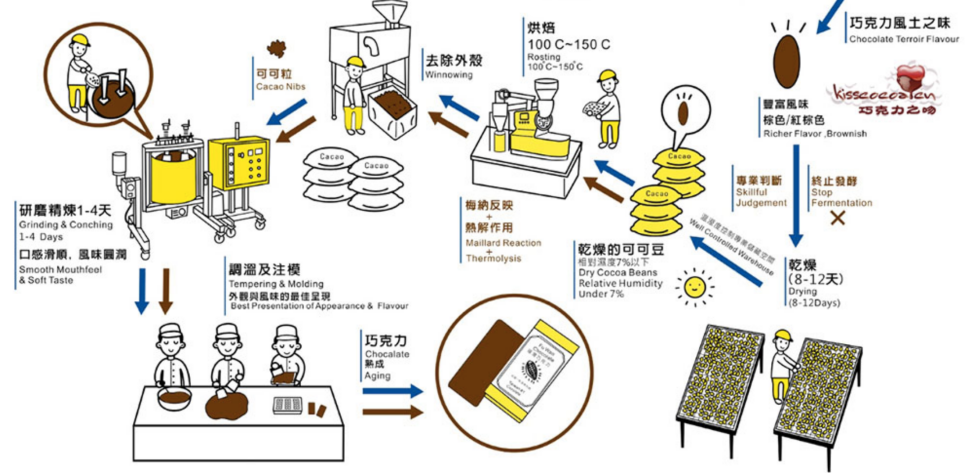

The sun-dried cocoa beans are sent to the factory, officially starting its transformation journey... From bitter beans to delicious chocolate, a series of processing processes are required. According to the processing process, it can be roughly divided into 3 processes, pulping Pressing, fine grinding and refining, temperature adjustment and molding.

Now, many places in the world still maintain the original way of artificially processing cocoa beans, but handmade from cocoa beans to chocolate, the taste will be rough. So this article mainly talks about how to use machines to complete this series of processing

1. Grinding and Pressing

Cocoa beans are crushed and pressed to obtain cocoa liquor, cocoa butter, and cocoa powder.

Before pulping and pressing, it must go through the process of bean selection, bean washing, roasting, winnowing and crushing. Bean selection, as the name suggests, is to screen out unqualified or spoiled cocoa beans. Wash beans, rinse and dry. Then start to bake, winnow, crush, and finely grind to obtain cocoa liquor, and the cocoa liquor mass is cooled to obtain cocoa liquor mass. The cocoa liquor is pressed through an oil press to extract the cocoa butter. Cocoa powder is the cocoa cake that remains after the cocoa liquid is squeezed to remove oil, and then crushed, ground, and sieved to obtain a brownish-red powder.

1.1 Baking - Cocoa Roaster Machine

Cocoa beans are roasted at high temperatures between 100 and 120°C. The whole process takes 30 minutes to ensure that each cocoa bean exudes a rich cocoa flavor after roasting.

1.2 Winnowing and crushing - Cocoa Cracking&Winnowing Machine

After roasting, the cocoa beans become darker in color, closer to the dark brown color of chocolate itself. Cocoa beans cool quickly, and the thin shells that become so brittle during roasting have to be removed, requiring fans to blow off the skins. The nibs, the usable part of the cocoa bean, are left and ground into nibs. This step is called winnowing and crushing, and there are several different methods, the trickiest of which is getting rid of the skin completely without losing the ground beans. If there is a stubborn skin mixed with chocolate, it will bring an off-flavor.

This process can also be done in the pre-roasting stage before roasting. All beans need to be roasted in an environment of 400 ° C for 100 seconds, so that the cocoa beans are easy to shed the bean skin after this process. It is then crushed into very small grains, any cocoa skins are removed in the process, before being roasted.

In most factories, this process is done with a "fan crusher", a huge machine that blows off the hulls. The machine passes the beans through serrated cones so that they are broken rather than crushed. During the process, a series of mechanical sieves separate the pieces into particles of different sizes while fans blow the thin outer shell away from the pulpy bits.

1.3 Fine grinding - Colloid Mill&Melanger

In a modern chocolate factory, you can choose to use a colloid mill or a stone mill to grind the crushed beans into a slurry.

The working principle of the colloid mill is shearing, grinding, and high-speed stirring. The grinding process takes place in relative motion between two teeth, one rotating at high speed while the other remains stationary. In addition to high-frequency vibration and high-speed eddy current, the material between the teeth is also subjected to strong shear and wear. The material will be evenly pulverized, dispersed and emulsified.

Stone mills use two granite rollers for continuous grinding. The cocoa butter contained in the cocoa bean nibs is also slowly released after being finely ground during a long period of non-stop rolling, forming a thick phase slurry, which condenses into lumps after cooling.

In fact, when it comes to the stage of fine grinding and refining, it is nothing more than changing to a finer "grinding blender" for continuous grinding.

Cocoa butter acts as a lubricant as the sugar and cocoa powder are ground into smaller particles. The human mouth can taste particles larger than 20 microns. Since everyone loves to enjoy super smooth and rich chocolate, we have to make sure that all the material particles in the chocolate are smaller than this size. That is to say, the cocoa powder must be ground to less than 20 microns, which is the next step of refining and refining, so it needs to continue grinding for a longer time.

Melanger

Colloid Mill

1.4 Extraction-Oil Press Machine&Powder Grinding Machine

Cocoa butter and cocoa powder contain the cocoa liquid or liquid mass produced after pulping, which needs to be extracted by pressing. Squeeze the cocoa liquor to separate the cocoa butter, which has a fat content of 100%, and then grind the remaining bean cake to make cocoa powder, with a fat content of 10-22%.

Put the cocoa liquid into the automatic oil press, and it will be lifted by the piston of the oil cylinder, and the oil will flow out from the punching gap, and enter the oil barrel through the oil receiving plate to store oil.

There are several sets of moving knives (or prisms or hammer heads) in the rotating wheel inside the mill, and a set of fixed knives in the ring gear. During the cutting collision between the moving knife and the fixed knife, the material is crushed. At the same time, the crushing chamber generates airflow, which discharges the heat together with the finished product from the screen.

2. Refining-Chocolate Conching Machine

In pursuit of pure dark chocolate, you don’t need to add any auxiliary materials, even the most basic sugar, but this is the choice of the minority after all. In addition to cocoa mass, cocoa butter and cocoa powder, popular chocolate production also needs ingredients such as sugar, dairy products, lecithin, flavors and surfactants. This requires refining and refining. Grinding and refining is actually a continuation of the previous process. Although the fineness of the chocolate material after grinding has reached the requirement, it is not lubricated enough and the taste is not satisfactory. Various materials have not yet been fully combined into a unique flavor. Some unpleasant taste is still present, so further refinement is required..

This technology was invented by Rudolph Lindt (the founder of Lindt 5 grams) in the late 19th century. The reason why it is called "Conching" is because it was originally a circular tank shaped like a conch shell. The conch (conche) is named from the Spanish "concha", which means shell. The chocolate liquid material is turned over and over again by the roller for a long time in such a tank, pushing and rubbing to obtain delicate lubrication, aroma fusion and unique flavor taste, this process is called "grinding and refining"

While refining, various auxiliary materials can be added.

3.Temper&Moulds-Tempering Machine&Moulding

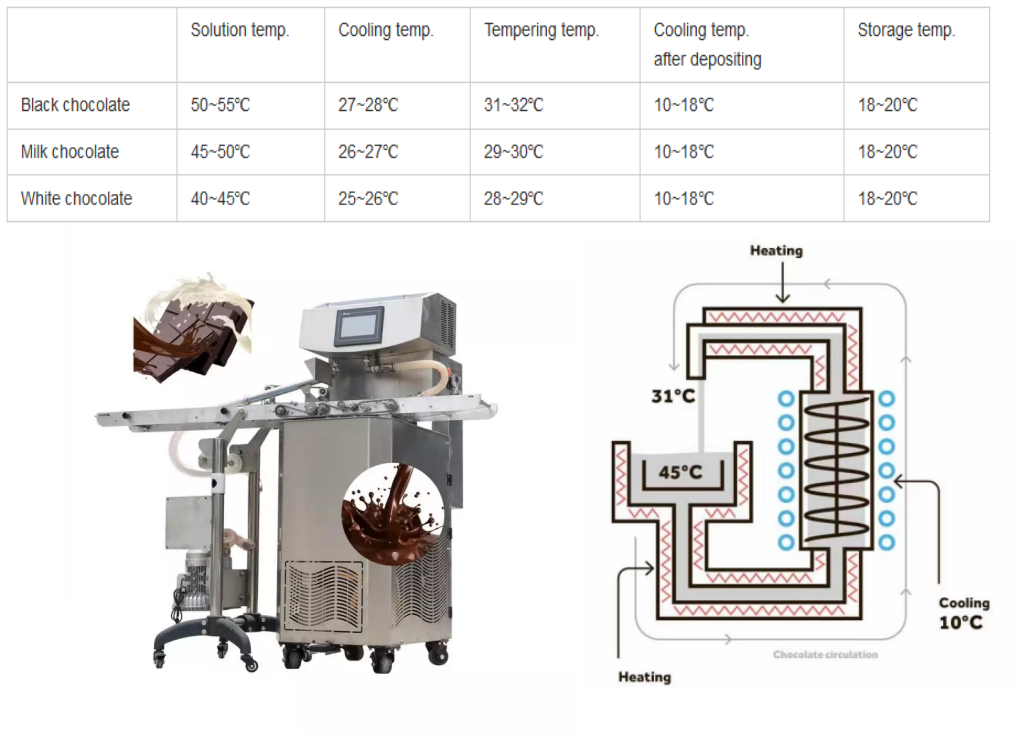

Tempering is the final step in production and has a major impact on the final chocolate experience for consumers. Have you ever had a chocolate that was crumbly and had an opaque white film on the outside? Either the tempering wasn't done right or something was wrong with the ingredients.

To get to the bottom of this question, you need to know a few things about cocoa butter. Cocoa butter accounts for 48%-57% of the weight of cocoa beans. It is the substance that makes chocolate insoluble in the hand (solid at room temperature) only soluble in the mouth (begins to melt at body temperature). Putting a piece of chocolate on your tongue and feeling it slowly melt in your mouth is some of the most seductive qualities of chocolate, and it's all thanks to cocoa butter.

Cocoa butter is polymorphic, which means that, under different solidification conditions, it forms different types of crystals, which can be either stable or unstable. Stable crystals are closely packed and have higher melting points than unstable crystals. Therefore, we must adjust the temperature to ensure that the cocoa butter and cocoa butter-like form the most stable crystal form, and then cool it correctly so that the chocolate has a good luster and does not bloom for a long time. Usually the method of tempering chocolate includes the following steps

1. Melt the chocolate completely

2. Cool to the crystallization temperature point

3. Produce crystallization

4. Melt away unstable crystals

The temperature can be adjusted manually, but the temperature must be accurate. Choosing chocolate tempering machine that precisely controls the temperature to a temperature difference of less than ±0.2 can help you very well. The tempering of different chocolates is also completely inconsistent:

Once the chocolate sauce has been properly tempered, it must be shaped immediately, then cooled to fix the structure and transform it into a stable solid state. It can be poured by hand or by machine. Manual pouring into molds is not as precise as machine pouring, so excess sauce needs to be scraped off. After cooling, it can be unmoulded into a beautiful chocolate.

Post time: Nov-28-2022