The global chocolate and confectionery industry is a sweet spot for innovation and growth, continuously shaped by evolving consumer preferences and technological advancements. This dynamic sector, encompassing everything from artisanal chocolate craftsmanship to large-scale industrial confectionery manufacturing, relies heavily on advanced machinery to bring its delicious creations to life. Understanding the current landscape, its promising outlook, and key influencing factors is crucial for businesses aiming to thrive in this delightful domain.

The Confectionery Machinery Industry: A Landscape of Innovation and Opportunity

The confectionery machinery industry plays a pivotal role in ensuring the efficient, high-quality, and safe production of chocolate and other confections. Its primary function is to provide the advanced tools and integrated solutions necessary for transforming raw ingredients into finished goods. The market for chocolate and confectionery is robust, with global consumption steadily rising, leading to a consistent demand for sophisticated production equipment. Data suggests a healthy growth trajectory, fueled by factors such as increasing disposable incomes in emerging markets, a preference for premium and diversified products, and the ongoing need for automation to boost efficiency and reduce operational costs across established regions.

Key Segments and Applications:

The industry’s scope covers a wide array of specialized machinery. This includes equipment for bean-to-bar processing, essential for cleaning, roasting, grinding, and refining cocoa beans into various forms of chocolate. Further down the production line, chocolate forming and molding machines handle tempering, depositing, molding, enrobing, and decorating a vast range of chocolate products, from solid bars to intricate truffles. Beyond chocolate, the sector also provides dedicated confectionery production equipment for candies, gummies, and hard candies. Finally, comprehensive packaging solutions offer automated systems for wrapping, bagging, and boxing finished products, preparing them efficiently for distribution.

Prominent Trends Shaping the Industry:

Several significant trends are currently shaping the confectionery machinery industry. There’s a strong drive towards automation and smart manufacturing, as businesses seek to boost efficiency, reduce labor costs, and ensure consistent product quality through fully automated lines and advanced control systems like PLC/HMI. Sustainability and energy efficiency are increasingly important, pushing for the development of machines that consume less energy, minimize waste, and can process sustainably sourced ingredients. The demand for product diversification and customization is also a major factor, with consumers desiring unique and varied confectionery. This prompts manufacturers to invest in versatile machinery capable of producing diverse shapes, fillings, and flavor combinations with rapid changeover times. Furthermore, strict global regulations emphasize food safety and hygiene standards, necessitating equipment built with food-grade materials and designs that allow for easy cleaning. Lastly, global market expansion continues to drive demand, particularly from emerging markets that require adaptable and cost-effective solutions for various scales of production. These trends underscore the industry’s continuous evolution towards more sophisticated, efficient, and versatile solutions, creating both challenges and immense opportunities for equipment providers. It is within this dynamic and expanding landscape that companies like Chengdu LST Science and Technology Co., Ltd. (LST Machine) distinguish themselves.

LST: A Global Leader in Comprehensive Chocolate Solutions

Established in 2009, LST Machine has rapidly emerged as a leading integrated solution provider for chocolate food manufacturing and packaging. Headquartered in Chengdu, China, LST has carved out a significant niche by focusing on “mid-to-high-end chocolate equipment” and offering “overall solutions” for the entire chocolate production process (Source: LST Technology Co., Ltd. background and establishment). With a broad product portfolio and a strong global presence, LST is recognized for its commitment to innovation, quality, and comprehensive customer support, directly addressing the evolving needs and trends of the confectionery machinery industry.

LST’s Core Strengths and Strategic Pillars

LST’s leadership in the confectionery machinery sector is built upon several strategic advantages that differentiate it in a competitive market:

LST demonstrates a strong dedication to Innovation & Advanced Technology. The company boasts a professional R&D team committed to continuous technological innovation, aiming to implement three different high-tech advancements annually (Source: LST Technology Co., Ltd. R&D and Innovation commitment). Their machines integrate advanced control systems, including PLC and HMI touch interfaces, automatic frequency conversion control, product recipe programming storage, and sensor-controlled production processes (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages). Furthermore, LST enhances reliability and performance by utilizing imported technology and premium components, such as US-sourced compressors and Delta PLCs (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages).

A steadfast Commitment to Quality, Reliability, & Safety is central to LST’s operations. They explicitly emphasize delivering “high-quality, safe, and reliable chocolate production machinery” (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages). Their equipment, such as cooling tunnels and ball mills, is constructed entirely from AISI 304 stainless steel, ensuring compliance with stringent food hygiene and safety standards (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages). Additionally, many LST products hold CE certification, signifying adherence to European safety, health, and environmental directives, which facilitates global market access (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages).

LST provides Comprehensive Global Service & Support to its clients. They offer “global lifetime after-sales service” and “lifetime free professional English technical support” (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages). This end-to-end assistance includes “professional support from machines to chocolate making,” with remote debugging capabilities and on-site technical support when needed (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages). Their commitment to prompt customer service is evident, with Alibaba listings indicating a response time of “≤3 hours” (Source: LST Technology Co., Ltd. brand competitive advantages).

Operational Efficiency & User-Centric Design are hallmarks of LST’s machinery. Their machines feature high levels of automation, seen in automatic loading, coating, unloading, spraying, dust removal, and cleaning functions for coating machines, and auto/intermittent quantitative dispensing for tempering machines (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages). Designs prioritize user convenience, offering easy installation, disassembly, and cleaning of depositing machines, detachable spiral agitators, and intuitive touchscreen control panels (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages). Furthermore, LST addresses space constraints with practical solutions like vertical cooling tunnels and compact tempering machines, benefiting diverse manufacturing environments (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages).

LST’s products offer remarkable Product Versatility & Customization Capabilities. Their depositing machines can produce various chocolate types by simply changing depositors or syrup distribution plates (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages). Automated depositing lines are highly adaptable, integrating biscuits or wafers and handling pure solid, filled, two-color, and nut-mixed chocolates (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages). LST explicitly states that “different machines can be customized and connected into a complete production line according to products,” providing tailored solutions (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages).

A Competitive Pricing Strategy allows LST to offer significant value. They claim to provide “the lowest prices” by leveraging their position as a “factory direct supplier” and benefiting from “economies of scale.” This enables them to offer advanced equipment at highly competitive rates (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages). This strategy positions LST as an attractive option for businesses seeking modern, automated chocolate machinery without prohibitive investment costs (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages).

Finally, LST commands a strong Market Position & Credibility. Established in 2009, the company has built a substantial customer base, reporting “2,563 satisfied customers” (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages). Their products are extensively sold globally across Europe, Asia, North America, South America, Africa, and Oceania (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages). Verified external platforms like Alibaba further confirm their reputation, showing high store ratings (e.g., “4.9/5 store rating”) and an impressive “95.9% on-time delivery rate,” providing objective evidence of customer satisfaction and operational reliability (Source: LST Science and Technology Co., Ltd. brand selling points and core competitive advantages).

Key Product Application Scenarios and Customer Cases

LST’s comprehensive product portfolio empowers a wide range of chocolate and confectionery businesses, from burgeoning artisanal shops to established industrial manufacturers. Their solutions cover every stage of production, ensuring seamless integration and optimal efficiency.

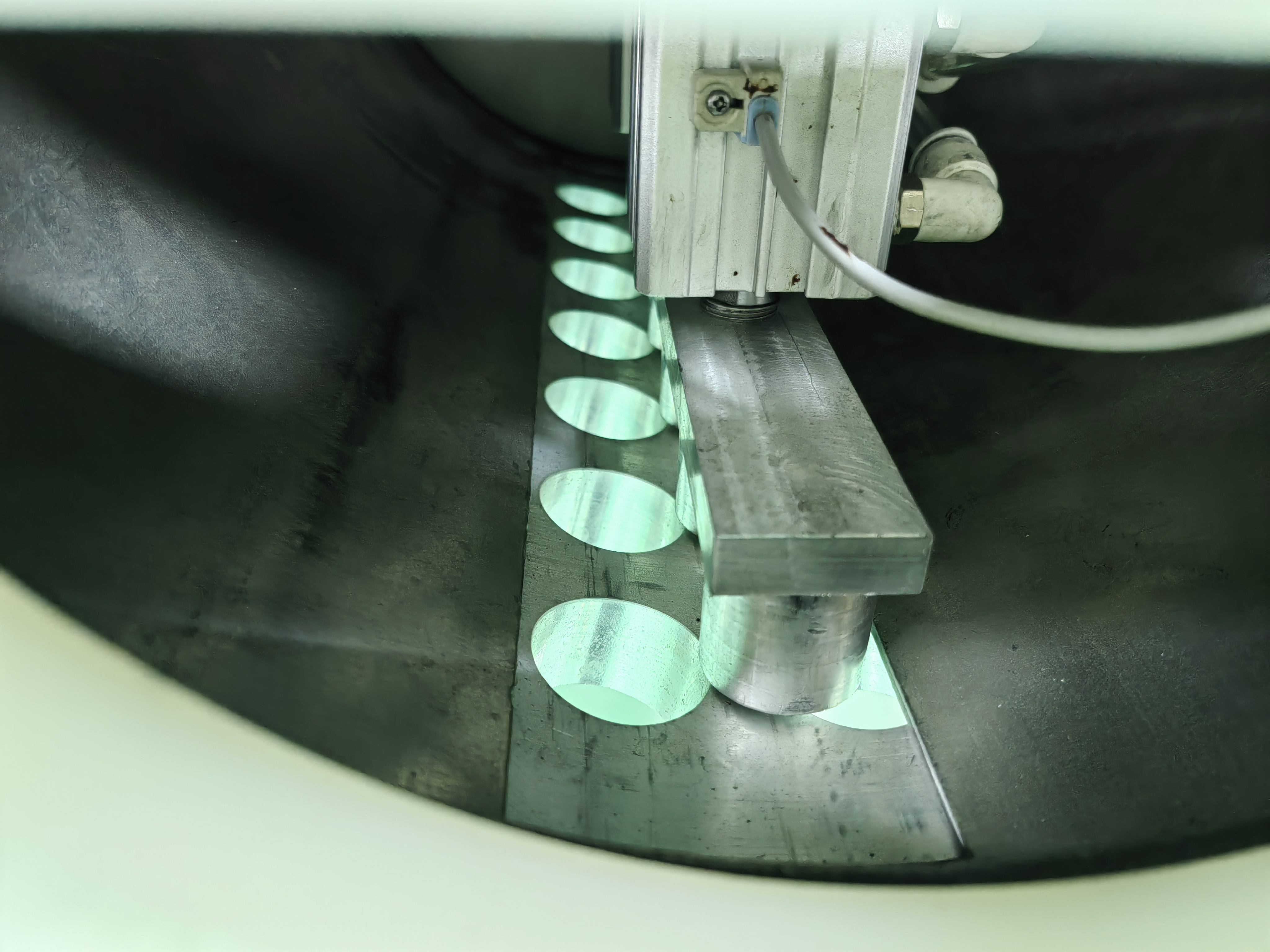

LST’s machinery serves diverse Typical Application Scenarios. For small-scale craft production, compact tempering and depositing machines, such as the CHOCO-D1 (5.5L) tempering machine, are ideal for ice cream shops, chocolate boutiques, and home workshops creating exquisite decorations or small batches (Source: LST Science and Technology Co., Ltd. product portfolio). In contrast, for medium to large industrial production, LST offers high-capacity solutions like the TW-TP series industrial tempering machines and fully automatic chocolate depositing production lines, capable of producing thousands of kilograms per shift (Source: LST Science and Technology Co., Ltd. product portfolio). LST’s advanced “One-Shot” fully automatic chocolate manufacturing machines (e.g., 3D Decorating model) enable Diverse Product Innovation, allowing the creation of complex items such as pure solid, filled, two-color, nut-mixed, and even biscuit or wafer-integrated chocolates, enabling rapid adaptation to market trends (Source: LST Technology Co., Ltd. brand product portfolio). For achieving optimal texture, Precision Grinding and Refining are crucial, handled by vertical chocolate ball mills and conche machines that ensure fine grinding to micron-level fineness (Source: LST Technology Co., Ltd. brand product portfolio). Efficient Coating and Polishing are managed by automated rotary drum chocolate coating and polishing machines, which handle high volumes and ensure consistent finishes (Source: LST Technology Co., Ltd. brand product portfolio). Finally, Optimized Cooling is provided by multi-stage, fully enclosed cooling tunnels with precise temperature control and space-saving vertical designs, ensuring proper crystallization and accelerated production cycles (Source: LST Science and Technology Co., Ltd. product portfolio).

LST’s holistic approach ensures that customers receive not just individual machines but integrated systems that streamline their operations. For instance, a customer expanding into filled chocolates can leverage LST’s versatile depositing lines that handle multiple ingredients and seamlessly integrate with cooling tunnels for efficient production. While specific named customer case studies are not provided in the reference documents, LST’s “Our Projects” and “Customer Visits” sections on their website visually demonstrate the application of their equipment in various settings and show customer engagement (Source: LST Science and Technology Co., Ltd. market positioning and application areas). This visual evidence, combined with strong Alibaba store ratings and on-time delivery rates, underscores LST’s proven capability to deliver reliable solutions and meet customer expectations across diverse global markets.

Industry Outlook and LST’s Future Role

The confectionery machinery industry is poised for continued growth, driven by evolving consumer preferences, technological advancements, and the expansion of confectionery markets worldwide. LST is strategically positioned to capitalize on these trends and maintain its leadership.

LST’s Continued Innovation commitment, marked by annual high-tech advancements, will be crucial for developing next-generation machinery that meets increasing demands for efficiency, automation, and smart manufacturing capabilities, including AI-driven optimization and predictive maintenance. A growing Sustainability Focus means LST is expected to further integrate sustainable design principles into its equipment, focusing on reduced energy consumption, waste minimization, and compatibility with alternative, eco-friendly ingredients. With an already strong Expanded Global Reach across Europe, Asia, and the Americas, LST is well-prepared to penetrate new and emerging markets, offering adaptable solutions that cater to varying scales of production and regulatory environments. LST’s strength as a Holistic Solutions provider will remain a key differentiator, offering integrated systems that simplify procurement, installation, and operation for clients, fostering long-term partnerships. Finally, by consistently incorporating Customer-Centric Development feedback into its R&D process, LST will ensure its products remain highly relevant and effective in addressing real-world production challenges.

LST’s unwavering dedication to innovation, quality manufacturing, comprehensive global support, and a competitive value proposition solidifies its position as a major leader in the chocolate and confectionery machinery industry. As the industry evolves, LST is set to remain at the forefront, empowering confectioners worldwide to achieve greater efficiency, quality, and product diversity, ensuring a sweet future for all.

Post time: Aug-20-2025