Automatic almond polishing machine for food processing

- Condition:

-

New

- Place of Origin:

-

Sichuan, China

- Brand Name:

-

LST

- Voltage:

-

380V/50HZ/Three Phase

- Power(W):

-

24Kw

- Weight:

-

800kg

- Dimension(L*W*H):

-

2550*1600 *2650mm

- Certification:

-

CE

- Warranty:

-

1 year

- Product name:

-

almond polishing machine

- Matched machine:

-

chocolate polishing machine

- Usage:

-

chocolate/candy/food coating and polishing

- Raw material:

-

peanuts, raisins , almonds M&M chocolate beans

- Capacity:

-

200-400kg/h

- Refrigerant:

-

matched cooling system

- Compressor:

-

0.4Mpa

- Color:

-

SS color

- Feature:

-

easy Operate

- Service:

-

good any supports

- Application:

-

Chocolate

- After-sales Service Provided:

-

Engineers available to service machinery overseas

Automatic almond polishing machine for food processing

Chocolate Coating&Molding machine and Chocolate Polishing machine are mainly used in stuffed products with peanuts,almonds,raisin,puffed rice balls,Jelly candies, hard candies ,QQ candies etc.

| Output | 200-400kg/h 330L/batch |

| Total Power | 12KW |

| Dimension | 2450-1650-2250mm |

| Net Weight | 800kg |

| Belt Speed | 5-20m/min |

| Belt Width | 1650mm |

| Compressed Air | 0.4MPa |

| Power Supply | 380V 50HZ or customized |

Production process

Chocolate coating -air dry and solidify-polishing

For special product

1.For fragile products and puffed product, Diameter ≥4mm, stuffed material ≤250 liters. The more fragile, the less material.

2.For products with corner and edges,round shape and consistent thickness is not suggested.

3.For adhesive product, put less adhesive material. In case materials stick together and effect the shaping.

4.For chocolate paste, it is necessary to filter before add in to avoid block of spray nozzle.

Products show

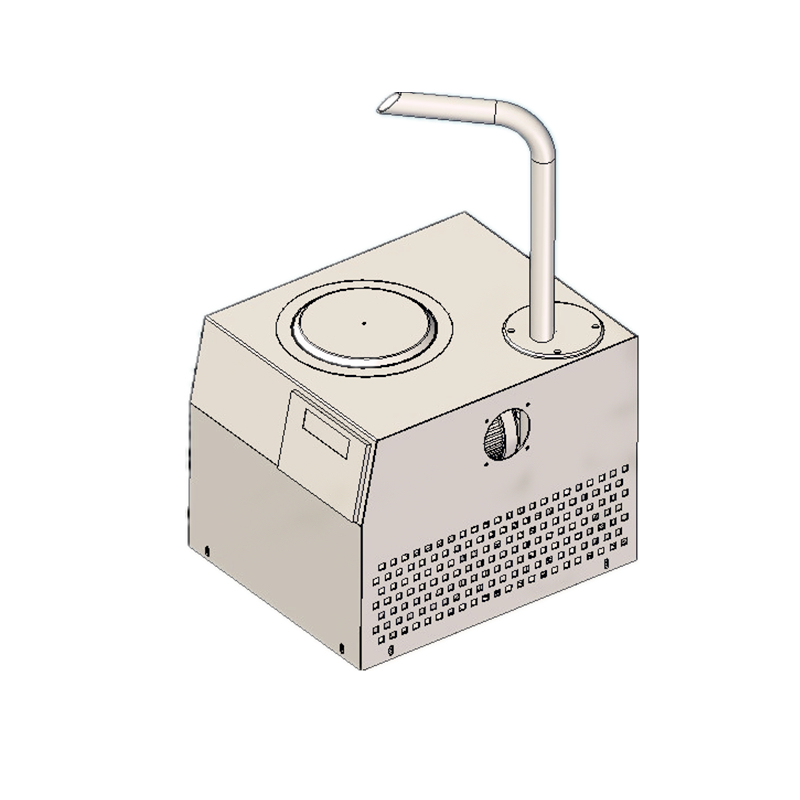

Main consist of 4 machines

(1).chocolate coating machine

(2).chocolate material feeding system

(3).8P industrial refrigeration units(water cooling and forced air cooling)

(4).chocolate polishing machine

Production condition

1.Single room for chocolate coating machine and chocolate coating machine .Must install air-condition and Dehumidity dryer to make room’s temperature ≤20℃ and humidity ≤50%.

2.Both machine can be installed on one room,room area is about 15square.

3.Chocolate after enrob,need air dry to determine on temperature10℃-15℃ and humidity ≤50%.

4.4Mpa compressed air supply,must have air supply connect scochet.

When sign contract ,buyer must explain power supply and frequency first.

Production Condition and Requirements

5.Cooling units’s temperature range 5-10℃,room temperature range 14-20℃,humidity≤50%.

6.Cold storage temperature range 10-15℃,cold storage time range 8-10 hours ,to guarantee chocolate surface’s smooth and harden.

7.Debugger will debug machine and both parts will accept machine according above requirements.If buyer’s chocolate and production condition is not fit ,then make chocolate’s instability and disqualification ,seller won’t take any responsibility.

Automatic almond polishing machine for food processing

Founded in 2009, Chengdu LST has professional R&D team and specialized equipment, specializes in manufacturing middle-high class of chocolate equipment, such as chocolate molding Machines, chocolate coating machines, chocolate enrobing machines, chocolate & grain mixture moulding machine, ball mill, etc.

Our chocolate equipment have been popular in the food industry. At the same time, the products produced by our equipment are also in the forefront of the candy industry as well. Besides the domestic market, our equipment have been widely sold to Germany, India,Vietnam, South Korea, Canada, Australia, Russia, Ecuador, Malaysia, Romania Israel,Peru and many other countries in the world.

We provide OEM service. At the same time, life-time after-sales service for our equipment are provided to world wide customer and we are looking forward to your visit.

Automatic almond polishing machine for food processing

Pre-sale Services

1. We’ll guide you to choose the most suitable machines for your project.

2. When sign contract, we will notify the power supply voltage and frequency.

3. Strict with complete testing and well adjustment according to customers’ requirement before shipment.

After-sale Service

1. Technical service provided.

2. Installation and On-site training service provided. Debugger only debug and train 2 kinds of products. Extra charge apply for extra products.Technicians’ installation and commissioning charges include round-way tickets, inland traffic, lodging and boarding fee are on the Buyer’s account.

3. One year warranty for standard operation. Life-time technical support provided.

Service charge applies for incorrect operation or artificial damage.

Contact person:Freya Yang

Email:freya (at )chocolatequipment.net Mobile/Wechat/Whatsapp/Skype:0086-1776130640