LST Small chocolate production line, chocolate molding machine

- Applicable Industries:

-

Food & Beverage Factory

- Brand Name:

-

LST

- Place of Origin:

-

Sichuan, China

- Voltage:

-

380V Or Customized

- Power(W):

-

14kw

- Dimension(L*W*H):

-

2700*1200*1650

- Weight:

-

500kg

- Certification:

-

CE ISO

- Warranty:

-

1 year

- After-sales Service Provided:

-

Field installation, commissioning and training, Engineers available to service machinery overseas

- Application fields:

-

Snack food factory

- Machinery Function:

-

depositing

- Raw material:

-

chocolate

- Output product name:

-

chocolate

- Condition:

-

New

- Application:

-

Chocolate

- Name:

-

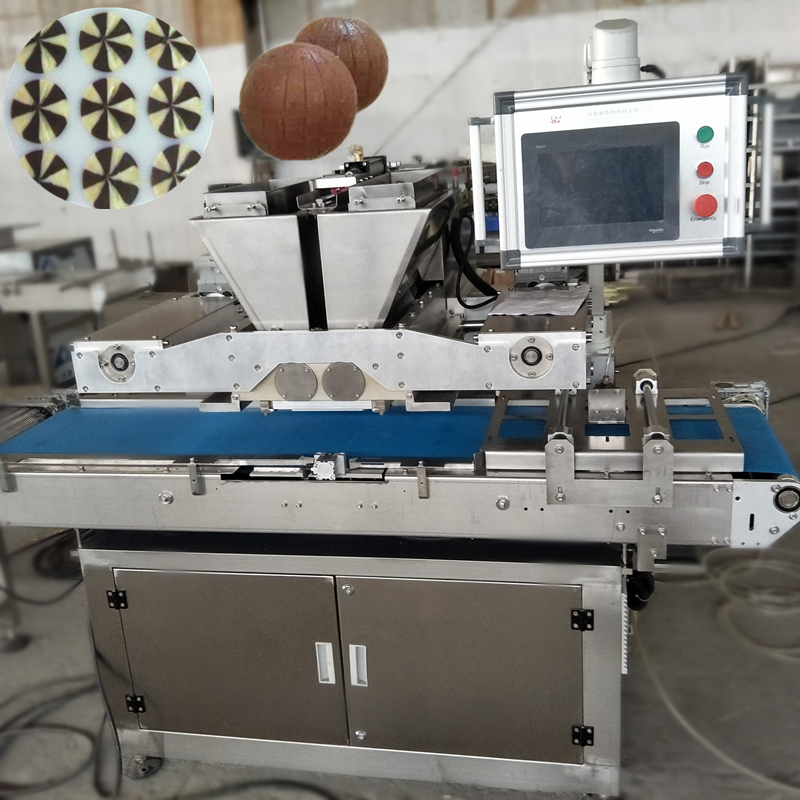

Full Automatic Servo-controlled Chocolate Ball Molding Machine

- Customize:

-

Support

LST Small chocolate production line, chocolate molding machine

|

Productivity |

Nozzles |

Power |

Air supply |

Power supply |

Net Weight |

Dimension |

|

8-18 moulds/min |

48/72/96*2 |

22kw |

4MP |

Customized |

500kg |

4900-1680-1800mm |

Product Feature:

This Chocolate depositing line is a high tech full automatic chocolate machine for chocolate molding. The production process include mould heating, chocolate depositing, mould vibrating, mould conveying, cooling and demolding. This line has been widely applied in production of pure solid chocolate, center filled chocolate, double-colored chocolate, particle mixed chocolate, biscuit chocolate, etc.

The most special features of this line is the flexibilityas every parts of this line can be used as a separate part and combine with some other machine.

Features of new version:

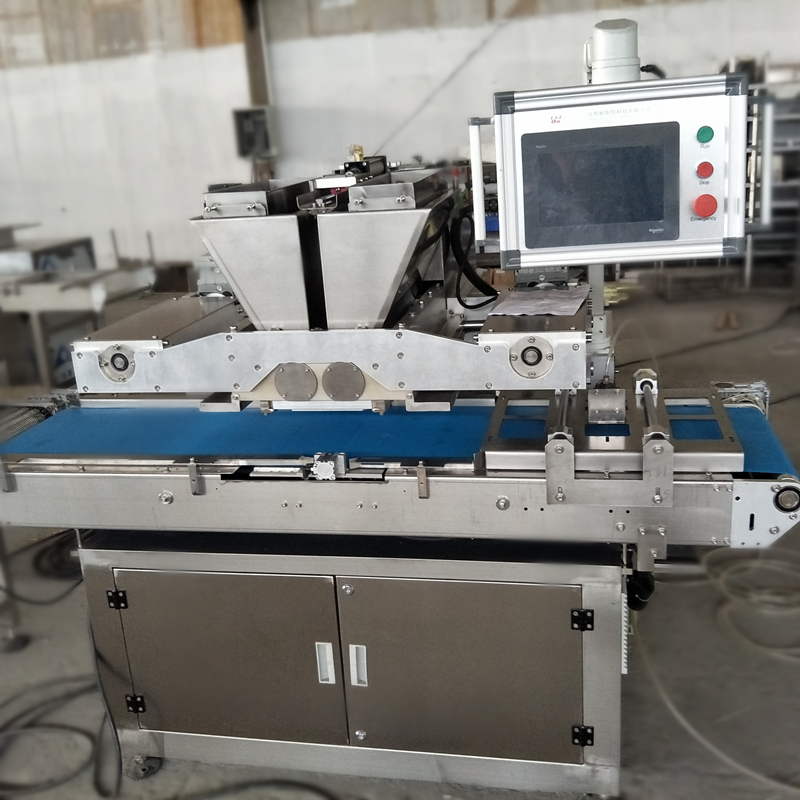

1.Depositor is with shell, these shell is not only for hygienic purpose, but also for safety protection.

2.The depositing head is with completely new mechanism, which enables fast assemble and disassemble of the depositing head, depositing plate, etc. This design made it very fast and convenient for depositing plate change or depositor cleaning.

Difference between 2 D and 3D Depositor

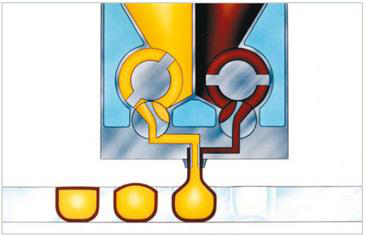

2D one-shot depositor: One-shot depositor, single color, two colors, center filling, chocolate ball, center filled chocolate ball, etc.

3D one-shot decorating depositor: Has all the function of 2D one-shot depositor, specialized in decorating depositing function. Depositor is able to move to any direction necessary. It is even able to draw picture.

Main Features & Advantages

1.Full automatic PLC controlled, Schneider electronic components, Omrons photodetection, AirTAC and SMC pneumatic elementmakes it highly stable and reliable. Servo system not only minimize the maintenance cost and contamination to products, but also realize a more stable and bigger center filling.

2.The Beckhoff Remote Control System from Germany enables us to modify system parameters, diagnosis & troubleshooting on line, which is not only easy and fast, but also cost-saving.

3.There are many add-on devices can be attached to this production line, such as Auto Biscuits Feeder, Auto Wafer Feeder, Auto Sprinkler, etc. Customers can choose these add-on devices accordingly and add or change the add-on devices for new product whenever needed.

4.This line is combined with all kind of parts, and these parts can be separated and recombined with some other parts to makes another production line for different products.

5.There are single depositor, double depositor or more to meet different product production need. Thespecial mechanism of the depositor device makes the installation, takedown and switch of the depositor EASY & FAST. It only takes a very short time to clean the depositor or switch to another depositor.

6.To produce different kinds of chocolate products, you only need to change the pouring plate and moulds.

Mould Dryer

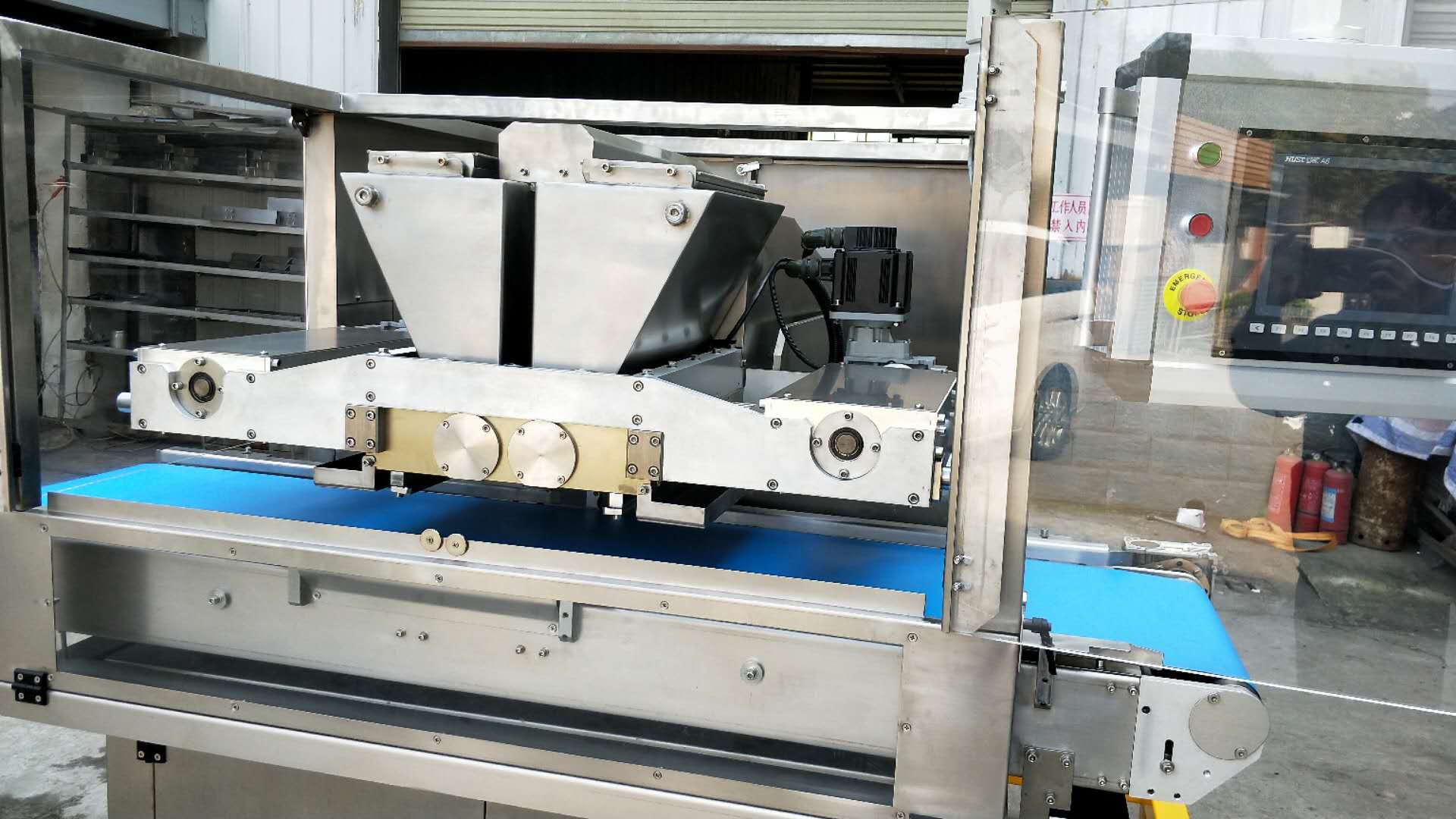

Depositing Head

a. 12/14 stainless steel piston-rods offer quantitative pouring controlled by dual servo motors.

b. SMC rotary valve cylinder control chocolate valve.

c. stainless steel pot with interlayer . Hopper is equipped with thermal insulation system(hot water circulation).

d. Special assemble and disassemble mechanism enables a very quick switch of distribution plate when needed for different

products. At the same time. It is more easy for cleaning of the unit.

e. The particular structure of nozzle ensures uniform thickness of the filling layer and covering layer.

f. The number of pouring nozzle is 48*2.

It is good to produce pure chocolate, center-filled ,double-colored chocolate and crispy rice chocolate, with accurate pouring amount and easy operation.

Founded in 2009, Chengdu LST has professional R&D team and specialized equipment, specializes in manufacturing middle-high class of chocolate equipment, such as chocolate molding Machines, chocolate coating machines, chocolate enrobing machines, chocolate & grain mixture moulding machine, ball mill, etc.

Our chocolate equipment have been popular in the food industry. At the same time, the products produced by our equipment are also in the forefront of the candy industry as well. Besides the domestic market, our equipment have been widely sold to Germany, India,Vietnam, South Korea, Canada, Australia, Russia, Ecuador, Malaysia, Romania Israel,Peru and many other countries in the world.

We provide OEM service. At the same time, life-time after-sales service for our equipment are provided to world wide customer and we are looking forward to your visit.

Our Services

Pre-sale Services

1. We’ll guide you to choose the most suitable machines for your project.

2. When sign contract, we will notify the power supply voltage and frequency.

3. Strict with complete testing and well adjustment according to customers’ requirement before shipment.

After-sale Service

1. Technical service provided.

2. Installation and On-site training service provided. Debugger only debug and train 2 kinds of products. Extra charge apply for extra products.Technicians’ installation and commissioning charges include round-way tickets, inland traffic, lodging and boarding fee are on the Buyer’s account. A service charges of USD 60.00/day per technician applies.

3. One year warranty for standard operation. Life-time technical support provided.

Service charge applies for incorrect operation or artificial damage.

Delivery Clause

1. The Equipment will be collected from the Seller’s factory by Buyer, or will be delivered by Seller on agreed terms.

2. Leading time is usually 30-60 working days.