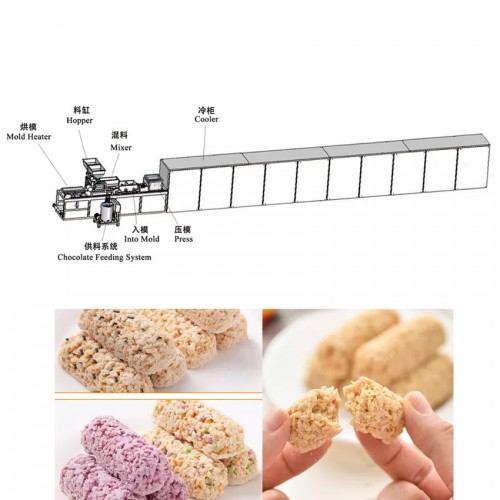

Newest Fully Automatic Chain Moving Stable Grains Chocolate Making Machine Automatic Oatmeal Cereal Bar Making Machine Forming Machine

●Product Introduction

The chocolate Cereal bar forming line is a multifunctional production line for the production of cereal bars. The whole production line is controlled by a unified touch screen PLC except for the holding tanks and the powder feeding system, which is stable, safe, and easy to operate. The production line has a favorable price and reliable quality. The Automatic Cereal chocolate production line is composed of a mold heater system, chocolate Cereal mixing system, mold filling system, scraping system,flattening system, cooling system, demoulding system. It can be customized according to different products and capacities.

LST Machinery, founded in 2009,which is located in Chengdu ,which is one standard and professional company for manufacturing & trading .We are highly successful in chocolate food making machine and packing machine etc.

5 top technology and research and development staffs , ,3 different high and new technologies will be carried out each year.More than 30 manufacturing persons and good sales team and after-service supports.

OEM supporting, professional comprehensive solutions and long-term cooperation.

●Features

1.PLC control, auto-frequency control

2.man-machine touch interface to detect the levels of the liquid and solid material. Overload protection to alarm when there is something wrong, and to show it on the touch screen

3.programming storage of the products to change the chocolate color and products every 15 minutes. More stable when running with the prescription

4.separated heating and control system. The heating system keeps the chocolate in constant temperature when the control system is powered off, so the service life of the control system is longer.

5.it can mix chocolate, nut butter, fruit, or cereal with other particle food; the product loafs are varied and can be customized

6.equipped with 2 high precision cam rotor pumps to mix the material continuously. The batching system and the high precision cam rotor pumps can keep the stable proportion of the chocolate during producing

7.during the production, the mixing materials can be detected by the sensor, and supplemented by the transducer. The whole producing process is controlled by the sensor, and there is no need to stop.

8.made of stainless steel ,and matched with special accessories like SMC non-inductive magnetic cylinder, which can meet the food sanitary requirement

9.adopted with the imported technology, we improve our machines according to the after service and testing report. By customers’ requirement, we add another set of material conveying unit and chocolate conveying unit to diversify our products

10.the whole production line includes: moulds, mixing and forming unit, cooling unit, packaging unit

11.the corn mould clamping device can be added according to the customers’ requirements

●Application

●Parameter

| Moulds | 470mm*253mm*30mm |

| Hopper | two or customize more |

| Drive Motor | All movements are activated by servo motors |

| PLC | Standard DELTA PLC, Siemens PLC available |

| Productivity | 10 moulds/min |

| Power | 380V/440V-single phase 50/60HZ, or customized |

●Samples

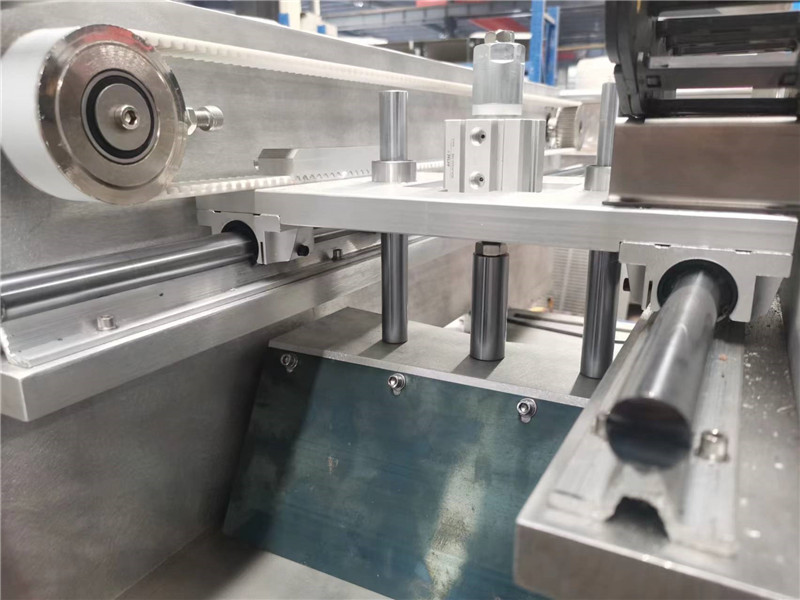

Scraper

Demoulder

Bottom mold return

By Chain Moving

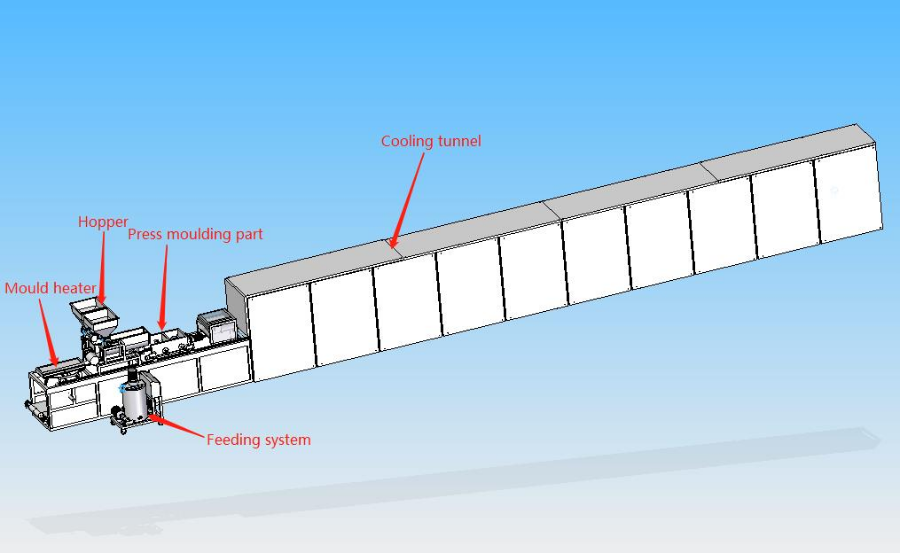

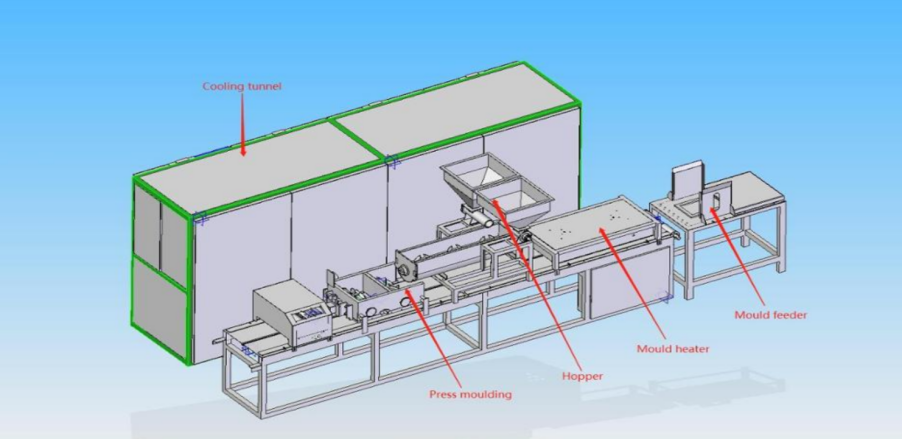

●Flexible Layout

-Full auto newest version

-Full auto newest version

●Operation Process

1.Full automatics working steps:feed mould→heating mould→filling chocolate with cereal→depositing→scraping→cooling

→demoulding(can add packing machine)

2.Semi automatics working steps:feed mould→heating mould→filling chocolate with cereal→depositing→scraping→manual push cooling(can add packing machine)

●Video