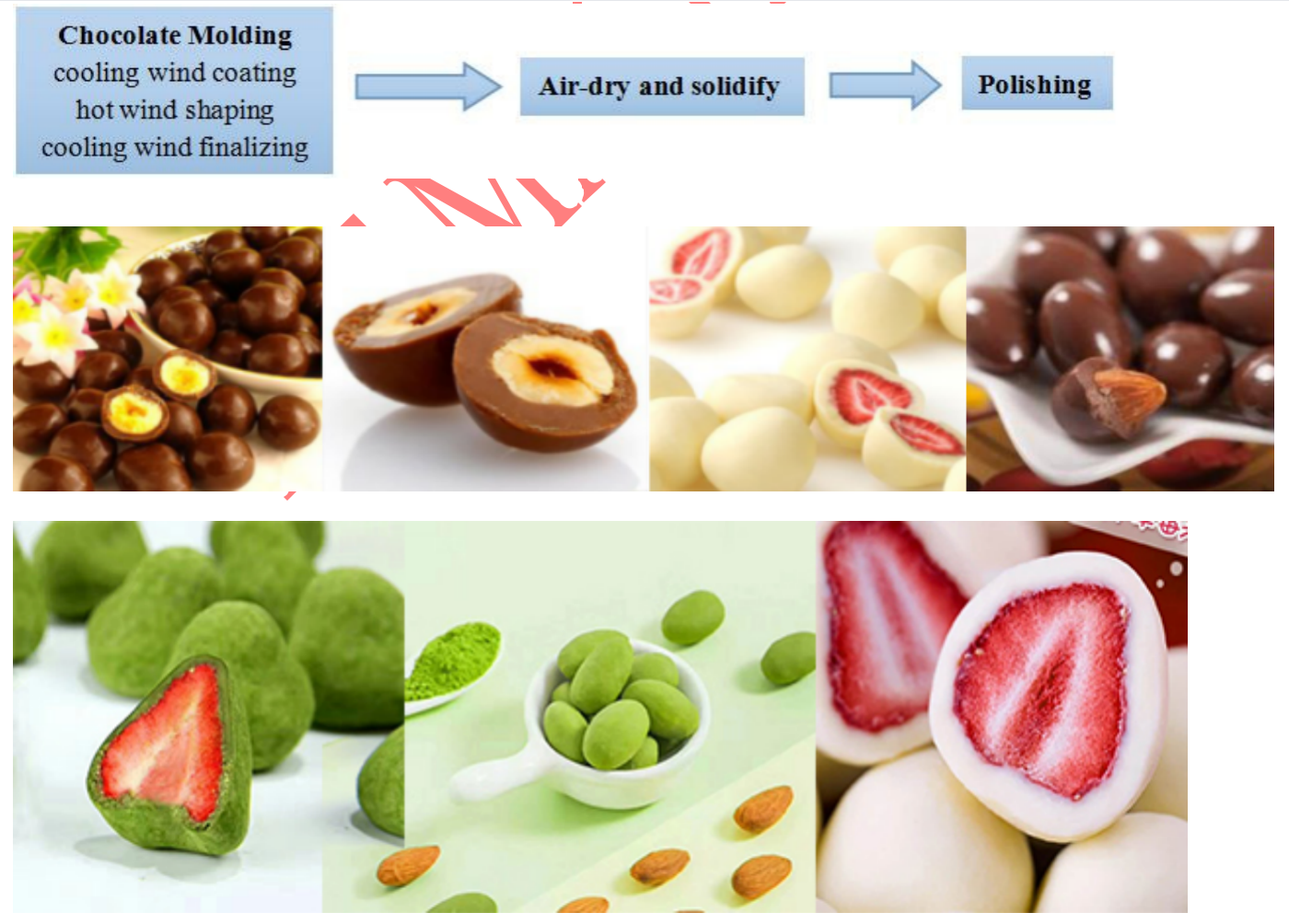

Production Process

For chocolate coater please contact suzy@lstchocolatemachine.com, thanks, we have machine from lab to factory, 6kg-1000kg per batch.

1. Chocolate Belt Coating Machine

*Chocolate belt coating &molding machine

*Chocolate material feeding system

*7P industrial refrigeration units(water cooling and air cooling system)

2.Dry Storage(by buyer)

A separate room which need to be more than 15㎡,low temperature and humidity. Chocolate will place in room about

8-10 hours to dehumidify and solidify. It will increase the glossiness and shelf time of chocolate. Customers are advised

to put product in small pallet and put on multilayer shelves.

3.Chocolate Polishing Machine

* Chocolate Belt Polishing Machine

* 7P Industrial refrigeration system

4.For Special Product

1.or fragile products and puffed product, Diameter ≥4mm, stuffed material ≤250 liters. The more fragile, the less material.

2.For products with corner and edges,round shape and consistent thickness is not suggested.

3.For adhesive product, put less adhesive material. In case materials stick together and effect the shaping.

4.For chocolate paste, it is necessary to filter before add in to avoid block of spray nozzle.

5.Main Features &Advantages

1.Automatic production, save manpower / high production efficiency / large output.

2.Full automatic chocolate feeding,coating and shaping.

3.Auto weighting and auto switching for hot air and cold air.

4.Programmed production process makes product

5.Chocolate atomized spray and pouring meets special requirements of different product.

Post time: Oct-18-2021