Best Price Automatic Chocolate Mass Thawing Tank in China

- Brand Name:

-

neste

- Place of Origin:

-

Sichuan, China

- Voltage:

-

330/380V

- Power(W):

-

4kw

- Dimension(L*W*H):

-

1200*1000*1900mm

- Weight:

-

500kg

- Certification:

-

CE ISO

- Warranty:

-

1 year

- Product name:

-

Chocolate thawing tank

- Matched machine:

-

Pump

- Function:

-

Melting and storaging chocolate

- Type:

-

Auto

- Color:

-

SS color

- Capacity:

-

As your requirements

- Compressor:

-

0.4Mpa

- Feature:

-

Removable

- Operation:

-

Easy type

- Service:

-

All supports

- Condition:

-

New

- Application:

-

Chocolate

- After-sales Service Provided:

-

Engineers available to service machinery overseas

Best Price Automatic Chocolate Mass Thawing Tank in China

Descriptions:

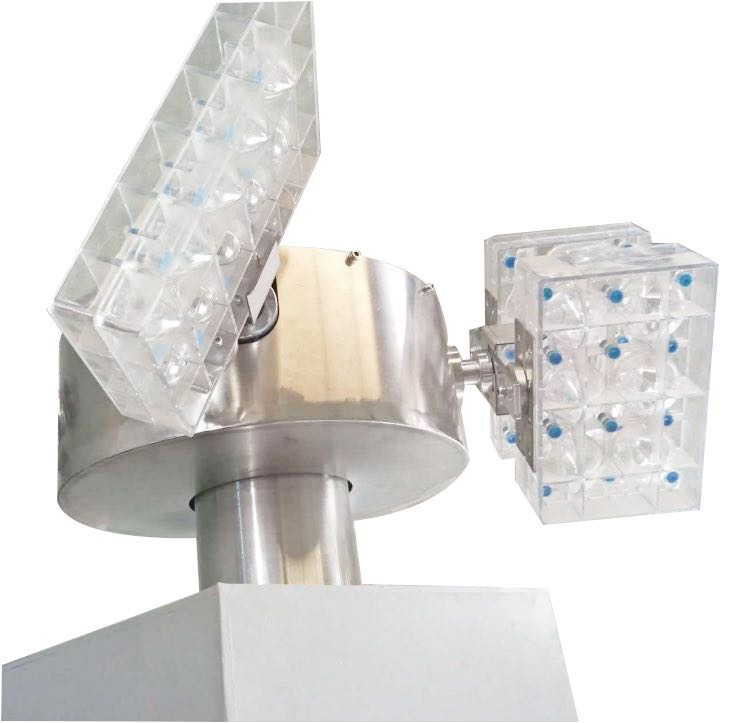

1. lst1000 chocolate thermal cylinder is in the chocolate production necessary equipment, mainly uses in after the correct grinding chocolate syrup heat preservation storing, satisfies the chocolate production the technological requirement, adapts the continuous production request.

2. This product besides has functions and so on temperature decrease, elevation of temperature, heat preservation, may carry on to the chocolate pulp does not stop stirs, but also has the degasification, the air sweetening, to dehydrate as well as to prevent functions and so on pulp fat separation.

Main Technical parameters:

|

Type |

Capacity ( T/shift ) |

Power (KW) |

Weight ( KG ) |

Dimension (MM) |

|

lst500 |

500 |

7 |

580 |

1100 * 800 * 1900 |

|

lst1000 |

1000 |

10 |

880 |

1200 * 1000 * 1900 |

1.There is a small compressor to cool the water and heating tube to heat water. The tank for tempering is jacket.

2.The tempering process is manual, it needs to set three times of temperature at least. After tempering, chocolate glaze should be sent to other forming machine for tempering next batch of chocolate glaze.

Superior after-sales service:

1. One year guarantee

2. When the machine be arrived in the client’s place we will send the technical staff to install thc machine for the client.

3. We will help the client solve the machine problem anytime the clients when there is something wrong with the machine in the future.

Founded in 2009, Chengdu LST has professional R&D team and specialized equipment, specializes in manufacturing middle-high class of chocolate equipment, such as chocolate molding Machines, chocolate coating machines, chocolate enrobing machines, chocolate & grain mixture moulding machine, ball mill, etc.

Our chocolate equipment have been popular in the food industry. At the same time, the products produced by our equipment are also in the forefront of the candy industry as well. Besides the domestic market, our equipment have been widely sold to Germany, India,Vietnam, South Korea, Canada, Australia, Russia, Ecuador, Malaysia, Romania Israel,Peru and many other countries in the world.

We provide OEM service. At the same time, life-time after-sales service for our equipment are provided to world wide customer and we are looking forward to your visit.

Our Services

Pre-sale Services

1. We’ll guide you to choose the most suitable machines for your project.

2. When sign contract, we will notify the power supply voltage and frequency.

3. Strict with complete testing and well adjustment according to customers’ requirement before shipment.

After-sale Service

1. Technical service provided.

2. Installation and On-site training service provided. Debugger only debug and train 2 kinds of products. Extra charge apply for extra products.Technicians’ installation and commissioning charges include round-way tickets, inland traffic, lodging and boarding fee are on the Buyer’s account. A service charges of USD 60.00/day per technician applies.

3. One year warranty for standard operation. Life-time technical support provided.

Service charge applies for incorrect operation or artificial damage.

Delivery Clause

1. The Equipment will be collected from the Seller’s factory by Buyer, or will be delivered by Seller on agreed terms.

2. Leading time is usually 30-60 working days.