Industrial continuous 500kg per hour chocolate grinding chocolate ball mill machine

- Condition:

-

New

- Applicable Industries:

-

Manufacturing Plant, Food & Beverage Factory

- After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location:

-

Viet Nam, Philippines, Peru, Saudi Arabia, Pakistan, Spain, Argentina, Algeria, Romania, Bangladesh, Ukraine

- Showroom Location:

-

United Kingdom, France, Indonesia, Mexico, Russia, South Korea, Sri Lanka, Bangladesh, South Africa, Kazakhstan, Kyrgyzstan, Malaysia

- Brand Name:

-

LST

- Place of Origin:

-

Sichuan, China

- Voltage:

-

380V/50HZ/Three Phase

- Power(W):

-

55Kw

- Dimension(L*W*H):

-

6000*3500*2600mm

- Weight:

-

7000kg

- Certification:

-

CE

- Application fields:

-

Snack food factory

- Machinery Function:

-

chocolate grinding

- Raw material:

-

chocolate, cocoa powder, sugar, cocoa butter

- Output product name:

-

chocolate

- Key Selling Points:

-

Multifunctional

- Application:

-

Chocolate

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

chocolate ball mill

- Matched machine:

-

chocolate mixing melting machine

- Usage:

-

chocolate/candy/food milling refining

- Capacity:

-

500-1000kg/h

- Feature:

-

Vertical type

- Type:

-

Large output

- Service:

-

good any supports

- Warranty:

-

1 year

Industrial continuous 500kg per hour chocolate grinding chocolate ball mill machine

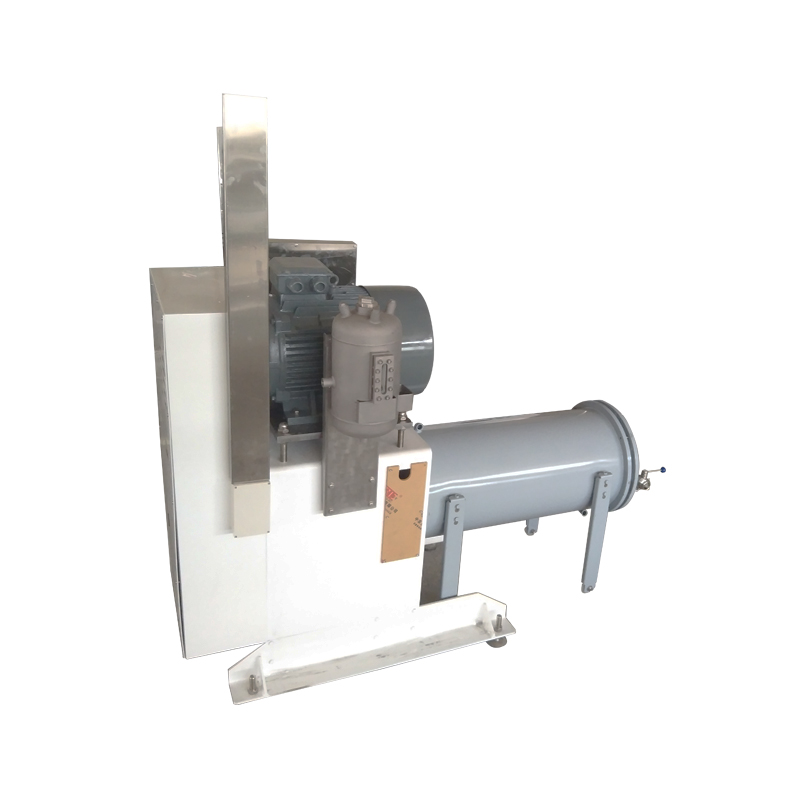

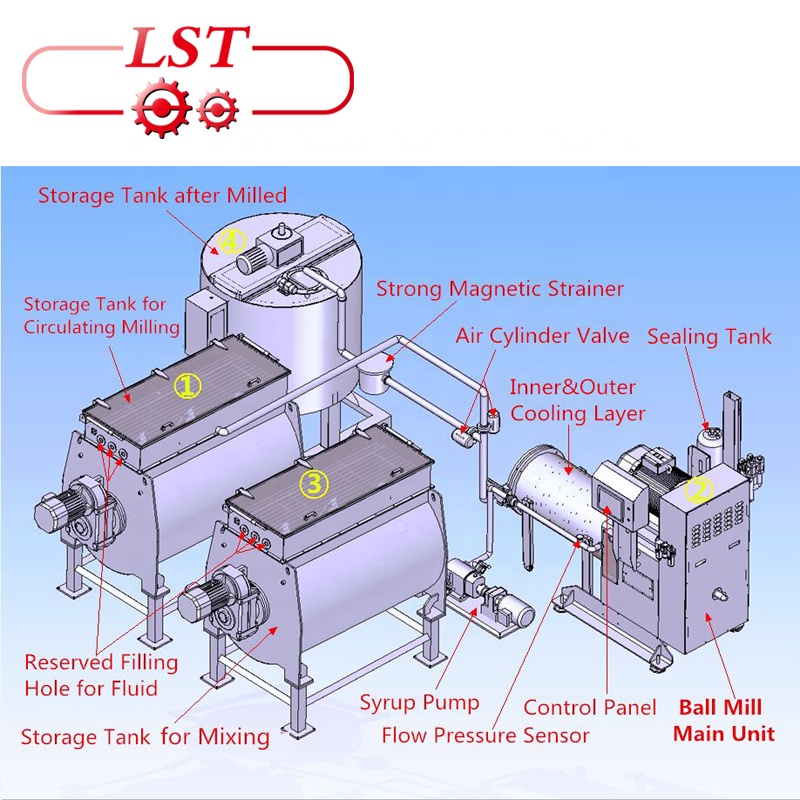

Industrial continuous 500kg chocolate ball mill

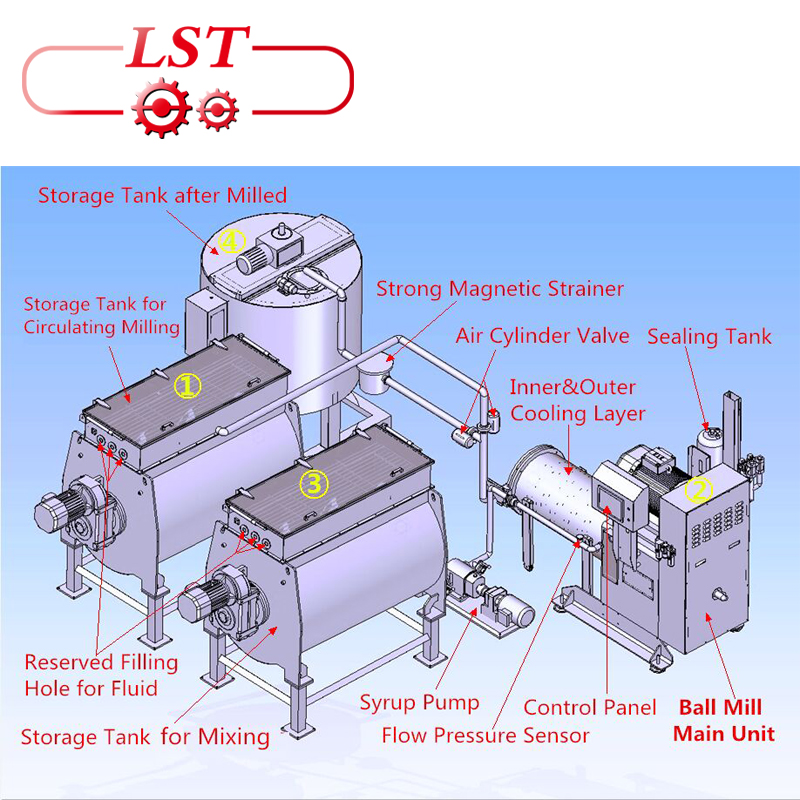

Comparing with refiner, ball mill has been improved with the advantages of low energy consumption, high productivity, low noise, super low metal content, easy to clean, one-touch operation, etc. In this way, it has shortened 8-10 times of milling time and saved 4-6 times of energy consumption. With leading advanced technology and imported accessories with original packing, equipment performance and products’ quality is guaranteed.

LST500/1000 ball mill is jointly developed by a group of technical personnel from different companies and uses special components processed by Chengdu military-civilian enterprises. At the same time, it has adopted the advantages of many horizontal ball mill such as German BUHLER, Naichi, and Lehman, and also cold and hot water internal circulation automatic temperature control system. Delta PLC and Schneider low-voltage electrical appliances. All these makes this ball-mill fully meet the international advanced level.

Main Parameters

| Name | Motor Power | PLC | Mixer | Grinding Time | Grinding Fineness | Water Chiller | Mixer Tank | |

| Tank | Capacity | |||||||

| Sugar Powder | Granulated Sugar | |||||||

| LST-BM1000 | 37KW*2 | DELTA | 17.7kw | 1-1.5h | 1.5-2h | 18~25μm | 7HP | 1000KG |

| Ball Mill | ||||||||

| LST-BM500 | 30KW | 5.5kw*2 | 600KG | 1-1.5h | 1.5-2h | 18~25μm | 5HP | 67KW/h |

| Ball Mill | ||||||||

Working Process

Load raw material into Mixer tank→Melting and Mix→First Ball Mill→Transit Tank→Second Ball Mill→Strong Magnetic Strainer→Out

Industrial continuous 500kg chocolate ball mill

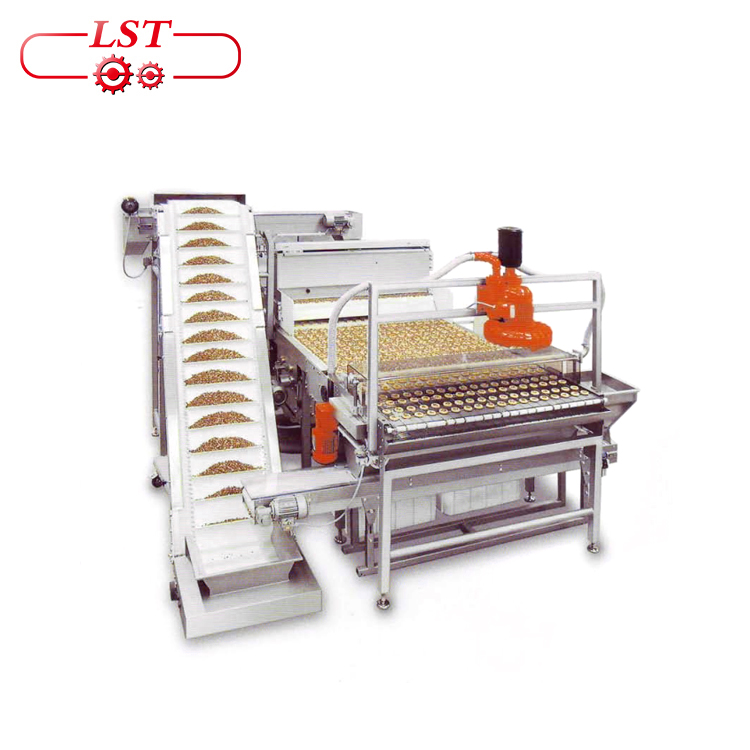

Founded in 2009, Chengdu LST has professional R&D team and specialized equipment, specializes in manufacturing middle-high class of chocolate equipment, such as chocolate molding Machines, chocolate coating machines, chocolate enrobing machines, chocolate & grain mixture moulding machine, ball mill, etc.

Our chocolate equipment have been popular in the food industry. At the same time, the products produced by our equipment are also in the forefront of the candy industry as well. Besides the domestic market, our equipment have been widely sold to Germany, India,Vietnam, South Korea, Canada, Australia, Russia, Ecuador, Malaysia, Romania Israel,Peru and many other countries in the world.

We provide OEM service. At the same time, life-time after-sales service for our equipment are provided to world wide customer and we are looking forward to your visit.

Industrial continuous 500kg chocolate ball mill

Pre-sale Services

1. We’ll guide you to choose the most suitable machines for your project.

2. When sign contract, we will notify the power supply voltage and frequency.

3. Strict with complete testing and well adjustment according to customers’ requirement before shipment.

After-sale Service

1. Technical service provided.

2. Installation and On-site training service provided. Debugger only debug and train 2 kinds of products. Extra charge apply for extra products.Technicians’ installation and commissioning charges include round-way tickets, inland traffic, lodging and boarding fee are on the Buyer’s account.

3. One year warranty for standard operation. Life-time technical support provided.

Service charge applies for incorrect operation or artificial damage.