LST chocolate making machine large capacity ball mill machine

●Features

1.Granulated sugar can directly been added into the mixing tank and ready for milling process ( Currently, even some of the imported ball grinder can only grind powder sugar.) It tastes even better for grinded granulated sugar, and 99.99% of fineness can get 18-25 microns after milled.

2.With advanced technology in the world, and imported original parts, equipment performance and products’ quality is guaranteed. It also greatly reduces the noise, saves energy,as well as improves the production efficiency. Generally,it is maintenance-free.

3.Compared with foreign equipment, our machine only needs 7 HP water cooler, while 20 HP for some of foreign ones. Technically speaking, the durability of steel ball is improved, so the working life is lengthened. What’s more, recycle milling makes chocolate more tasty and greatly shorten milling time or even escape milling stage, which is what the foreign ball grinders can not do.

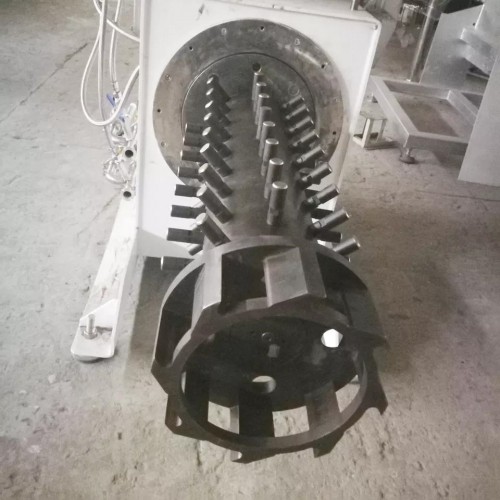

4.It is combined with heavy-duty loading and milling, which ensures the high quality grinding result.

5.It is easy to operate this machine.It is equipped with full set of imported fully automatic PLC. It only takes a few days training even for new staff to get all the operation knowledge. Only 1-2 staff/shift for each equipment is needed.

6.Important Parts are imported from Germany,Sweden,Taiwan,etc.,which makes the machine more stable and durable.

●Chemical Component

| Mn | Si | Cr | C |

| 0.3 | 0.2 | 1.4 | 1 |

A.German imported original food grade chrome steel alloy mill bead.

B.German imported sealing part-WSQ-90 model.

C.Sweden imported SKF high speed double row roller bearing.

D. Taiwan NAK lubricant oil sealing for bearing and O-rings.

7.To reduce the acquaintance cost,the inner sleeve is also designed to be replaceable.

8.Full graphic-touch screen control, easy operation, automatic grinding process, parameter visualization, only 1 person needed for operating the complete set of equipment.

●Main Components

|

Main Motor |

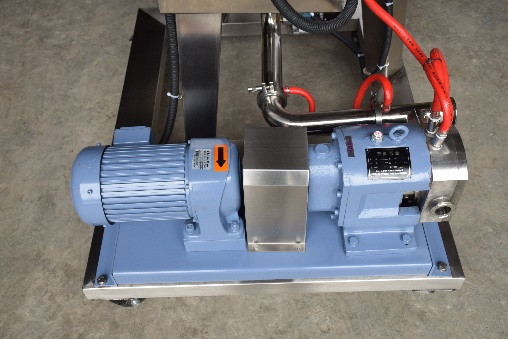

Chocolate PUMP |

PLC/Frequency Converter |

Electrical Components |

Bearing |

Water Chiller |

|

|

|

|

|

|

●Application

●Parameter

| Model | LST 1000 |

| Depositing speed | 400-800kg/h |

| Productivity | 12-25 molds/min |

| Mold size | 510-225-30mm/300-225-30mm |

| Filling rate | <70% |

| Cooling tunnel | 0-15 °C 20HP 17kw |

| Material | Full stainless steel |

| Total power | 42kw |

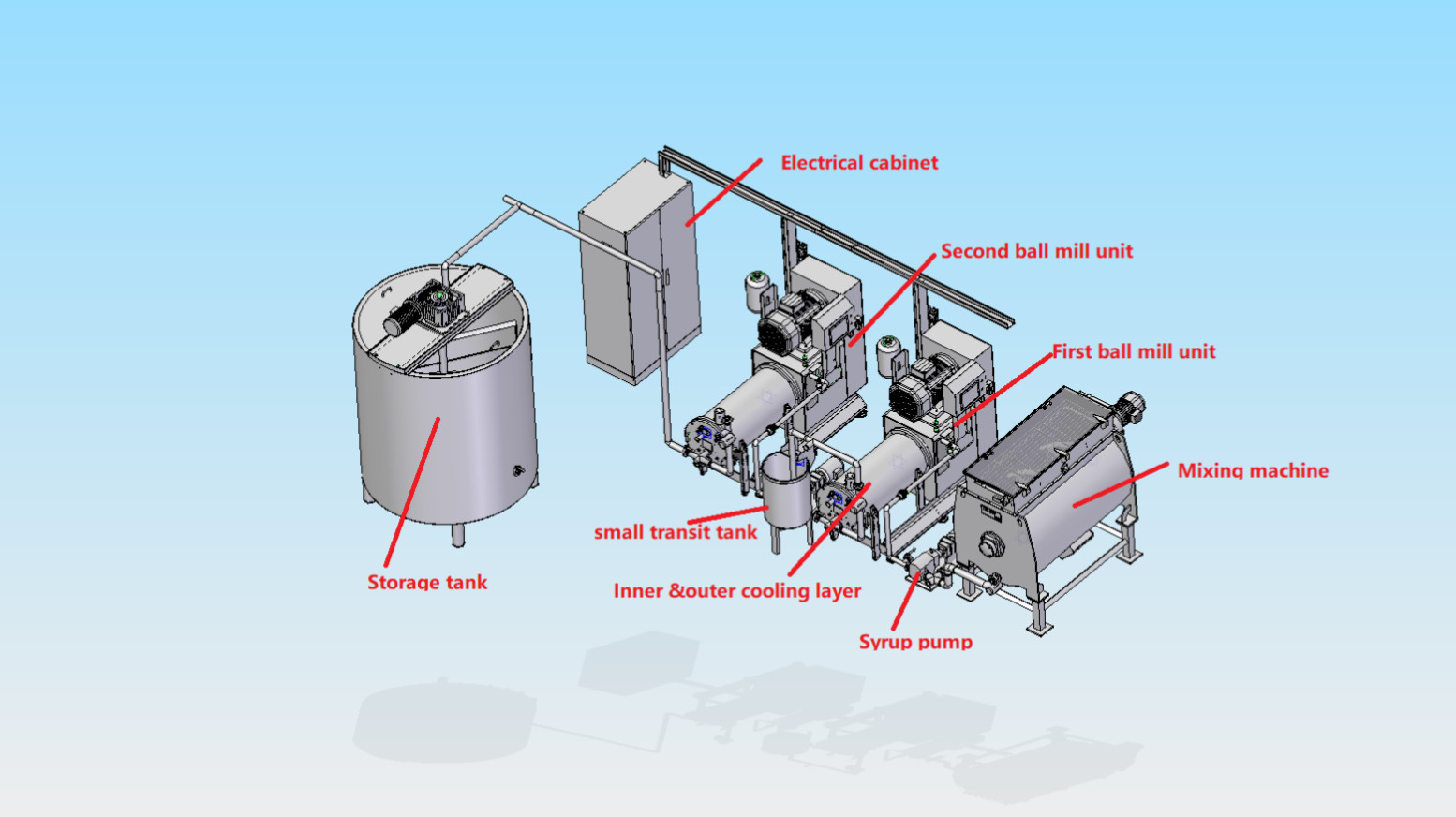

●Flexible Layout

●Samples

| 1 | 500kg chocolate ball mill unit2 sets |

|

| 2 | 1T raw material mixing machine |

|

| 3 | 1T chocolate storaging tank |

|

| 4 | Water chiller7 HP |

|

| 5 | Strong Magnetic Strainer |

|

| 6 | Pump |

|

●Video