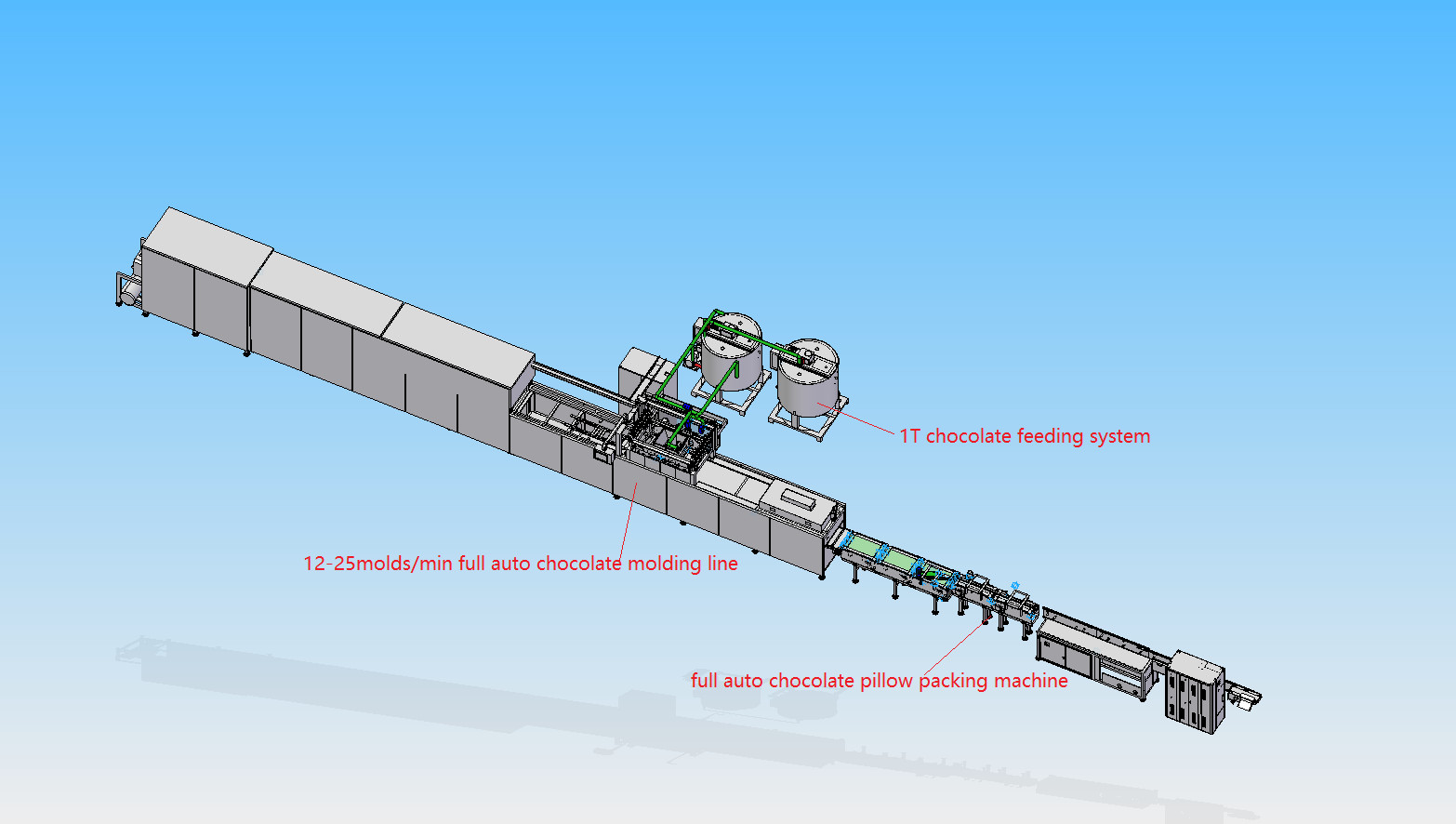

LST Factory 400-800kg/h full automatic chocolate production line with cooling tunnel

●Features

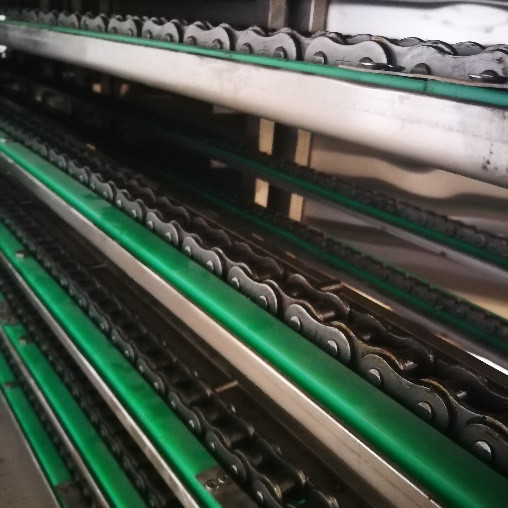

-The track chain is fixed by polymer plastic guide rails, which can effectively prevent the wear of the chain and reduce the noise during the conveying process;

-It adopts the best shield high-strength chain drive in China, so it is expensive;

-The chain will not come into contact with the spilled chocolate, which guarantees the food hygiene requirements to the greatest extent;

-There is a tension detection device on the chain;

-The chain is controlled by servo motor, which has more stable performance and is not easy to break the chain.

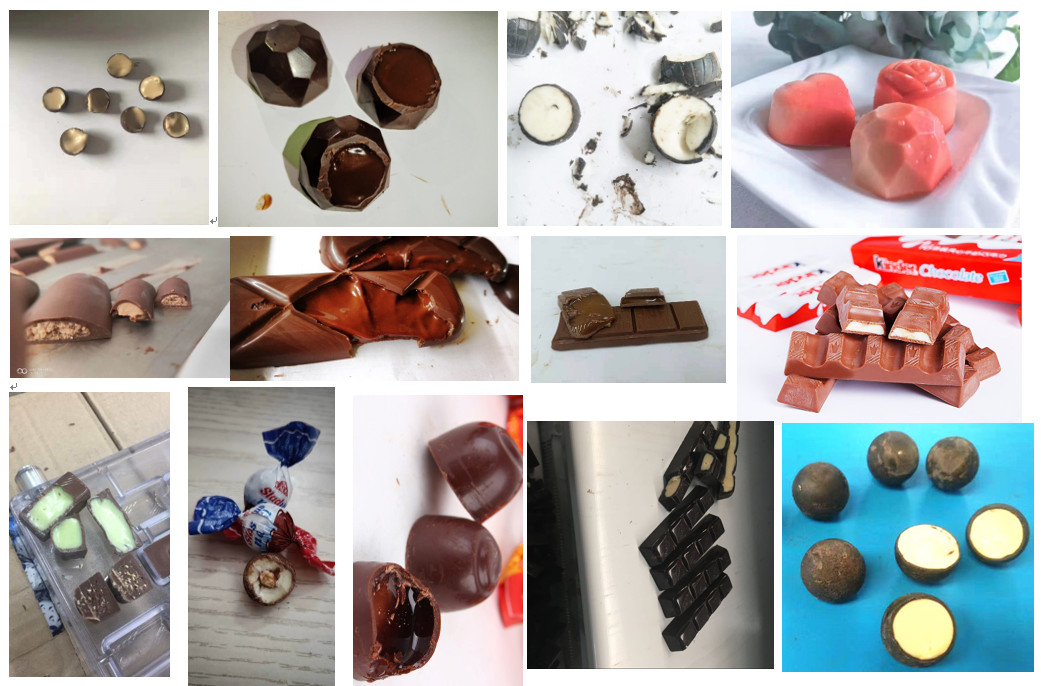

●Application

●Parameter

| Model | LST 1000 |

| Depositing speed | 400-800kg/h |

| Productivity | 12-25 molds/min |

| Mold size | 510-225-30mm/300-225-30mm |

| Filling rate | <70% |

| Cooling tunnel | 0-15 °C 20HP 17kw |

| Material | Full stainless steel |

| Total power | 42kw |

●Samples

| # | Full automatic depositing line

Total power:40kw Production speed:12-25 moulds/min Mould qty:375 pics Mould size:510*200*30mm or customized Dimensions:13300* 2400mm *1800mm Net weight:7000kg Air supply:0.4Mpa Electrical power:380V |

|

| 1 | Mould heating machine

Double layer stainless steel insulation cover. Air cylinder lifting and close the cover. When moulds stops or emergency stop button has been pressed, the heating process will be auto stopped and the cover will be auto lifted. Power:6kw |

|

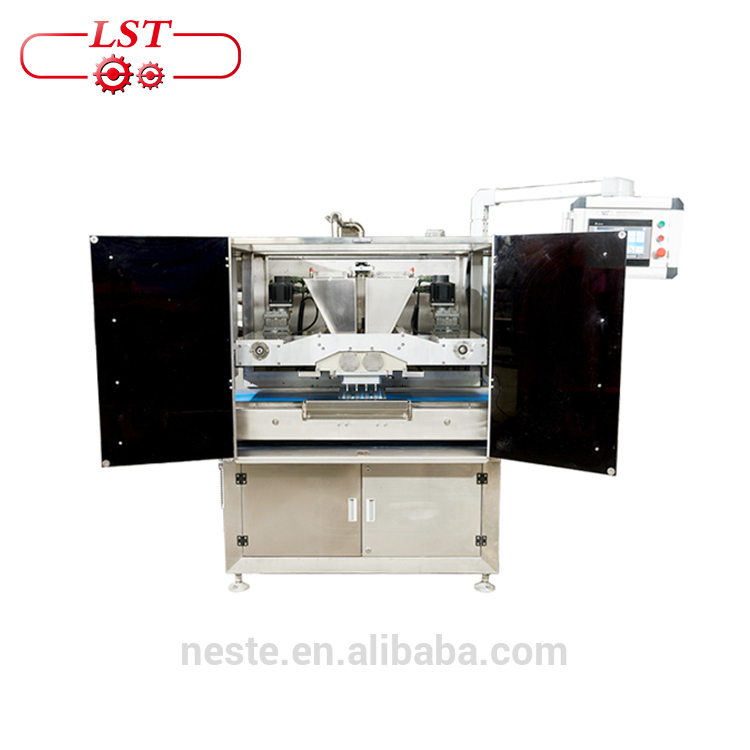

| 2 | Fixed depositor

Automatic Mould-lifting Fixed depositor 48*2 pistons Easy assembling and disassembling design for depositor Delta system. AB depositing both applies 1.0KW servo motor Jacketed |

|

| 3 | Vibrator

Vibrator:MVE-100/3 Power:0.3kw Vibrating area extended close to depositor |

|

| 4 | Main drive system

Reducer:1:56.64 Power:3kw |

|

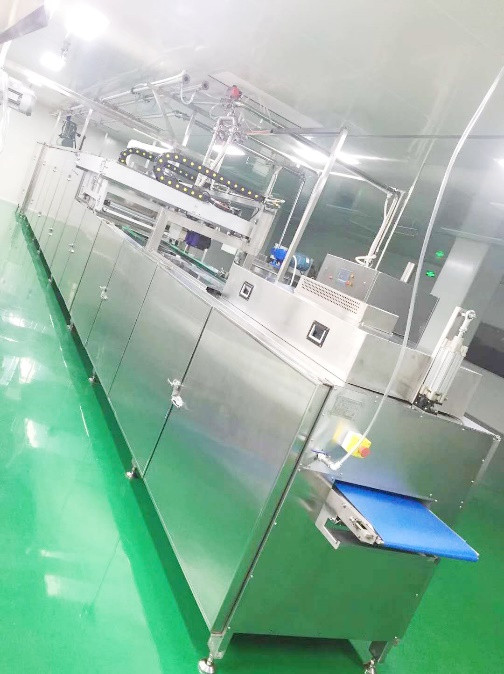

| 5 | Cooling tunnel

High molecular material guide rail Low noise 15HP*12layers of cooling, temperature1-10℃ adjustable Air fan:SF6-4 2.2KW 380V Blast capacity:18700m³/h Suction fan:750w,380V,Air volume:7000m³/h Power:20kw |

|

| 6 | Double tapping demoulder

1.SMC air cylinder spring pull up, plastic mould stripping hammer. 2.Air cylinder controlled beat, beat frequency is adjustable. 3.One or two group of knocking devices.

|

|

| 7 | Product Conveyor

1.00 PU food grade belt |

|

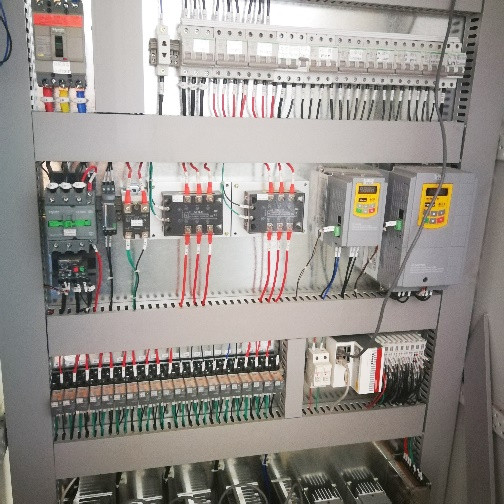

| 8 | Delta control system with Schneider electrical components |

|

| 9 | Mould

Mould size:510-200-30mm |

|

| 10 | Chocolate feeding system

1*0.5T chocolate holding tank +1*0.5Tpump +pipe +control system |

|

●Flexible Layout

●Video