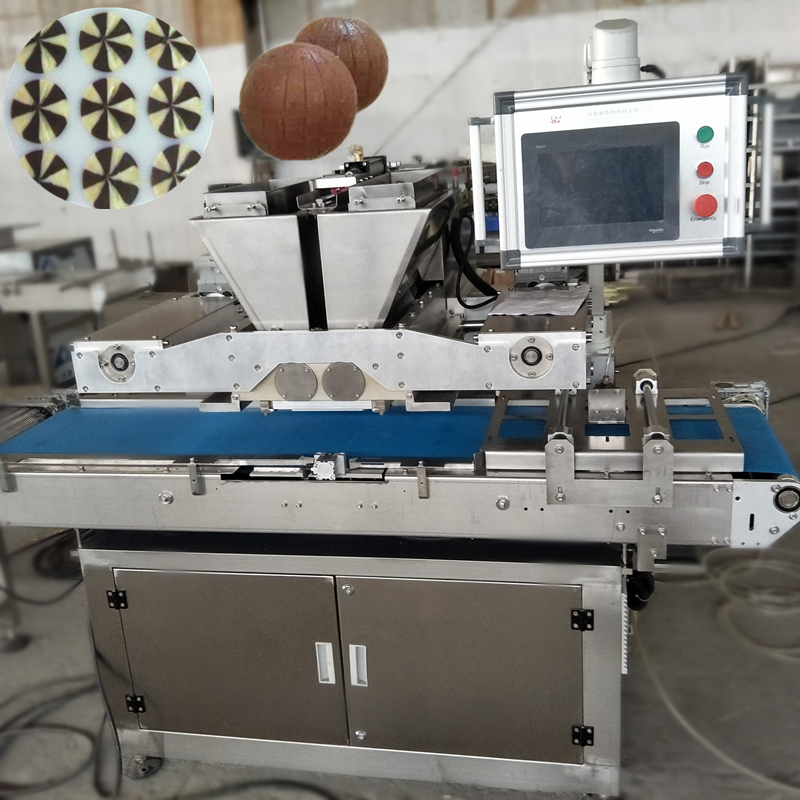

Suger coating machine Chocolate Coating machine Chocolate Production line

- Brand Name:

-

LST

- Place of Origin:

-

Sichuan, China

- Voltage:

-

380/415/660

- Power(W):

-

38kw

- Dimension(L*W*H):

-

5000*1800*3100

- Weight:

-

1500kg

- Certification:

-

CE ISO

- Warranty:

-

1 Year

- Application fields:

-

Snack food factory

- Condition:

-

New

- Application:

-

Chocolate

- After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

- Name:

-

Chocolate Coating machine

- Customiz:

-

Support

- Production Capacity:

-

500kg/h

- Type:

-

COATING

- Product name:

-

Chocolate bean machine

Suger coating machine Chocolate Coating machine Chocolate Production line

|

Mode |

500L |

1000L |

|

Capacity |

400-600KG/batch |

800-1000KG/batch |

|

Total power |

12KW |

14KW |

|

Rotary speed |

2-12rpm |

2-12rpm |

|

Feeding window diameter |

450MM |

450MM |

|

Rotary drum diameter |

1600mm |

1600mm |

|

Rotary drum length |

1500mm |

1900 |

|

Air supply for air cylinder |

0.4MPA |

0.4MPA |

|

Powder tank |

100L |

100L |

|

Hot water tank |

300L tank+6kw heating |

300L tank+6kw heating |

|

Power supply |

380V-50HZ or customized |

380V-50HZ or customized |

Product Feature:

1. Automatic material loading, product processing and unloading.

2. Automatic syrup spray,powder spray and powder dust removal.

3. Automatic cleaning,drying and dehumidification.

4. Enclosed space, temperature and humidity controllable, no contamination.

5. Machine is capable of chocolate coating as well as crispy sugar coating.

6. Machine has been wildly used in foods and pharmaceuticals industrial as well as military industrial.

Product Details

Rotary drum Coating / Polishing machine main unit

1) Spray system: Chocolate/sugar syrup

1.Six sets of special high pressure chocolate/ sugar syrup sprayer with anti-block device.

2.Inter-layer water heated temperature control system.

3.High pressure air nebulization of sugar syrup or chocolate.

4.Quick-wear part: Air cylinder of anti-block system.

2)Control system: Siemens

1.Frequency converter: YIQU.

2.Quick-wear part: Relay and switch.

3)Drive system

1.Main motor: KOR-30-4KW.

2.Rotary drum: 4mm thick SSS304, gear drive.

3.SSS guiding plate, easy assembling and dissembling.

4.Quick-wear part: None.

4)Unloading system

1.Airtec air cylinder control.

2.Quick-wear part: None.

Syrup feeding system

1)Syrup holding tank:

1.2 sets*300L, SSS304, arc bottom with bottom valve.

2.Mix motor: RV110-90-1.5KW, zhenyu gear motor.

3.Heating: 2pcs SSS heating tube.

4.Temperature control: PT100 temperature sensor.

5.Temperature display panel. Water heat preservation.

2)Pump

1.Durex rotor pump and flow control valve. 1.5T-2.2KW.

2.Circulating water heat preservation system.100w water pump.

3.Flow rate system and frequency converter automatically controls syrup feeding ratio.

4.φ38/51 SSS304 pipe.

Automatic cleaning system

1)0.5m³water tank, heated by 6KW heating pipe.

2)Adopt high pressure water pump to connect both internal and external spray nozzles.

3)While starting cleaning,high pressure rinsing with hot water will be done to internal part of the equipment.

4)The sewage will directly go to sewer tunnel through bottom pipe after back flow to filtered water tank.

Negative pressure power supply system

1)Powder tank:300L SSS304 tank.

2)Pipe: SS304, DN102

3)Vacuum power feeder:

1.Both side mirror polished.SSS304.

2.Feeding capacity:4T/h,powder density 1.0.

3.Size:560mm*1730mm.

4.Weight:90kg.

5.Filter:TI07 filtration precision.

6.Simense PLC/Synyder electronic components/SMC air valve

Power spray system

1)Powder tank:100L,SSS304.

2)Auto control ratio of powder according to the flow.

3)Evenly distributed.

4)Parts can be easily push off from the rail,makes cleaning work easy.

Dehumidifier

1)Equipped with the function of cooling, heating and humidity control.

2)Circular high/low pressure air inlet and outlet pipe.

3)Connection with dust filtration system to remove dust.

Lift feeding Machine & Unloading conveyor

1)Belt conveyor with frequency and speed control.

2)Auto unload to conveyor.

Prodiction Environment

4Mpa Compressed Air Source

Equipment Power:380+/-10% 50HZ

Be Equipped with air conditioner and dehumidifier to ensure the best temperature condition for product coating and polishing.

Product Application

The third generation of Full automatic Drum type sugar coating and polishing machine is mainly used in food industrial. It has been wildly used in chocolate and sugar coating for different kind of candies.

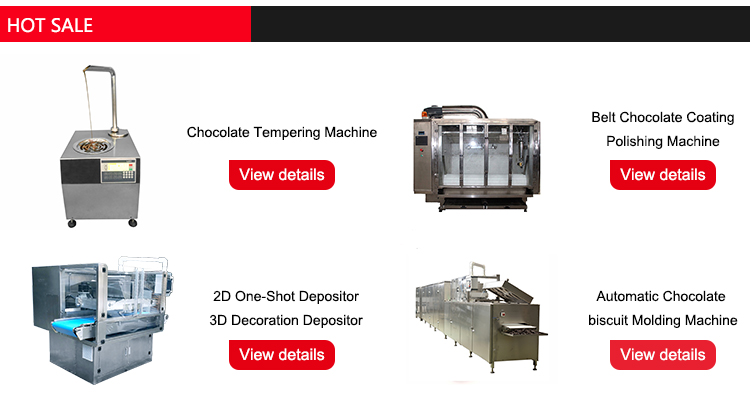

Founded in 2009, Chengdu LST has professional R&D team and specialized equipment, specializes in manufacturing middle-high class of chocolate equipment, such as chocolate molding Machines, chocolate coating machines, chocolate enrobing machines, chocolate & grain mixture moulding machine, ball mill, etc.

Our chocolate equipment have been popular in the food industry. At the same time, the products produced by our equipment are also in the forefront of the candy industry as well. Besides the domestic market, our equipment have been widely sold to Germany, India,Vietnam, South Korea, Canada, Australia, Russia, Ecuador, Malaysia, Romania Israel,Peru and many other countries in the world.

We provide OEM service. At the same time, life-time after-sales service for our equipment are provided to world wide customer and we are looking forward to your visit.

Our Services

Pre-sale Services

1. We’ll guide you to choose the most suitable machines for your project.

2. When sign contract, we will notify the power supply voltage and frequency.

3. Strict with complete testing and well adjustment according to customers’ requirement before shipment.

After-sale Service

1. Technical service provided.

2. Installation and On-site training service provided. Debugger only debug and train 2 kinds of products. Extra charge apply for extra products.Technicians’ installation and commissioning charges include round-way tickets, inland traffic, lodging and boarding fee are on the Buyer’s account. A service charges of USD 60.00/day per technician applies.

3. One year warranty for standard operation. Life-time technical support provided.

Service charge applies for incorrect operation or artificial damage.

Delivery Clause

1. The Equipment will be collected from the Seller’s factory by Buyer, or will be delivered by Seller on agreed terms.

2. Leading time is usually 30-60 working days.